In the UHV DC transmission system, used to measure DC current and transmit the measurement results to the DC control and protection equipment, fiber optic current sensor can measure the high current in the line with high precision, provide accurate current data for the stable operation of the system, and guarantee the normal performance of the control and protection functions of the UHV DC transmission system in the process of high-power, long-distance transmission.

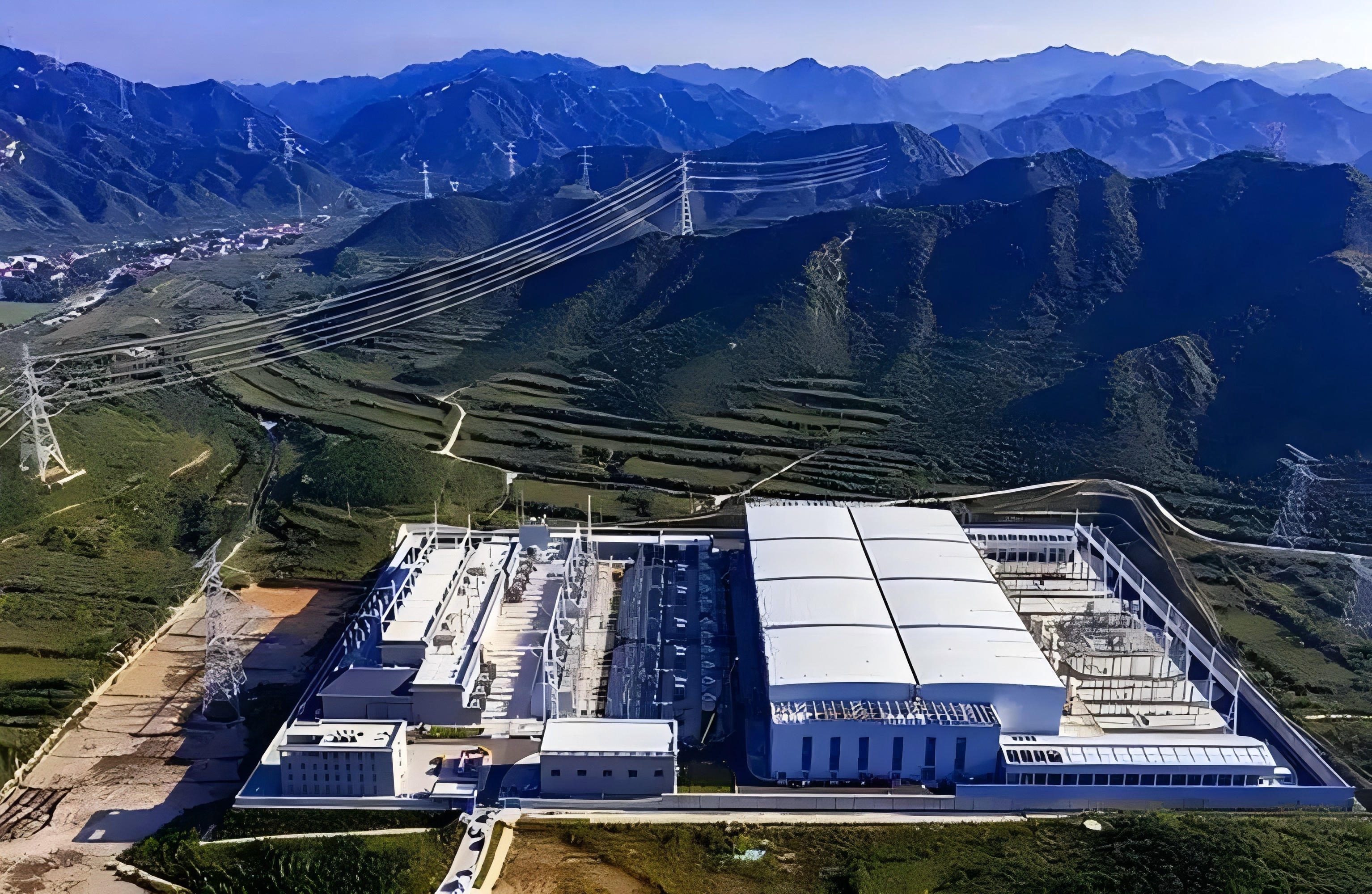

Mainly used in ± 200kV Zhoushan flexible DC transmission, ± 500kV Zhangjiakou - Beijing flexible DC transmission and other projects. As the DC side of the flexible DC transmission system is prone to generate large fault current when the fault, the transient performance of the current measurement device requires high, fiber optic current sensor can quickly and accurately measure the current, provide key data support for the rapid protection and control of the flexible DC transmission system, to meet the needs of the project on the rapid detection and suppression of fault current, to enhance the safety and stability of the power system.

Jiangsu Ru dong ± 400kV offshore wind power flexible DC transmission project, is China's first far offshore wind power via DC transmission project, as the world's highest voltage level, the largest transmission capacity of the offshore wind power flexible direct project, creating eight world firsts, large-scale development and construction of China's large-scale far offshore wind power is of great significance as a demonstration. Our fiber optic current sensor, installed in ± 400kV transmission line, real-time monitoring of current changes in the line, for grid operation status assessment, trend control and fault diagnosis to provide data support. When the line overload, short circuit and other faults, it can quickly and accurately detect the current abnormality, trigger the protection device in time, cut off the circuit, and protect the line and equipment safety.

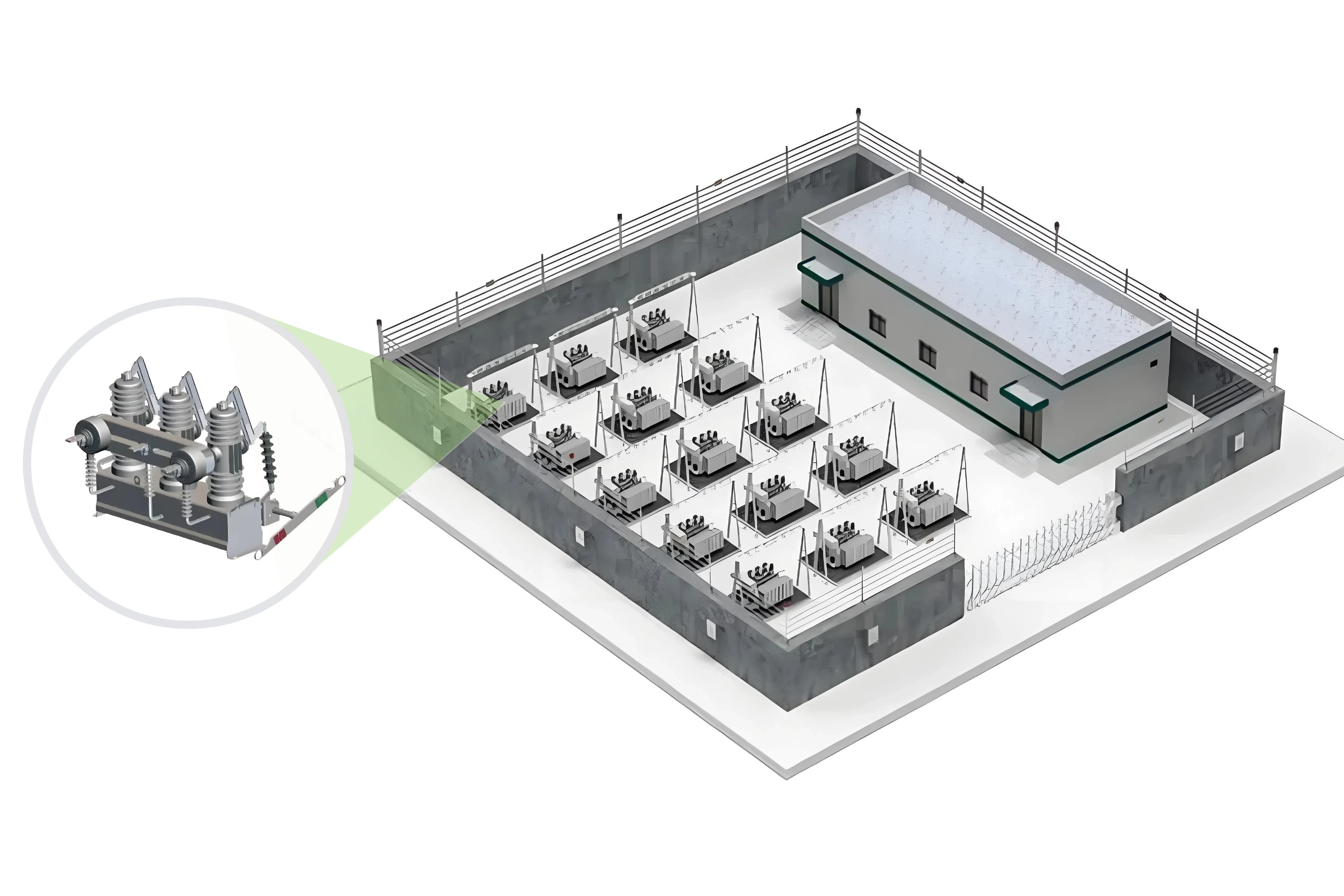

In DC distribution network, fiber optic current sensor can be used to measure the current in the DC distribution lines of ±35kV, ±10kV, etc., to realize real-time monitoring and protection of DC distribution system. It can also be used for current measurement when distributed energy sources are connected to DC distribution network to realize accurate monitoring and control of distributed power output current.

For the safety of nuclear power plants, the new generation of substation equipment in nuclear power plants needs to monitor milliamperes - level small currents in real-time. Due to strong magnetic field interference, limited installation space, and issues with salt and alkali corrosion in the field environment, SIO has specifically developed core components, improved the sensor winding process, and designed a special skeleton structure. The device has passed multiple dynamic simulation tests and is widely supplied to several nuclear power plants across the country.

Applying cathodic protection current to pipelines provides corrosion protection. However, stray currents from grounding systems near railways or substations may interfere with the cathodic protection current, leading to over-protection or under-protection of certain parts of the pipeline, which can result in corrosion issues. By measuring the cathodic protection current, stray current interference can be detected and addressed in a timely manner, ensuring the safety of the pipeline.

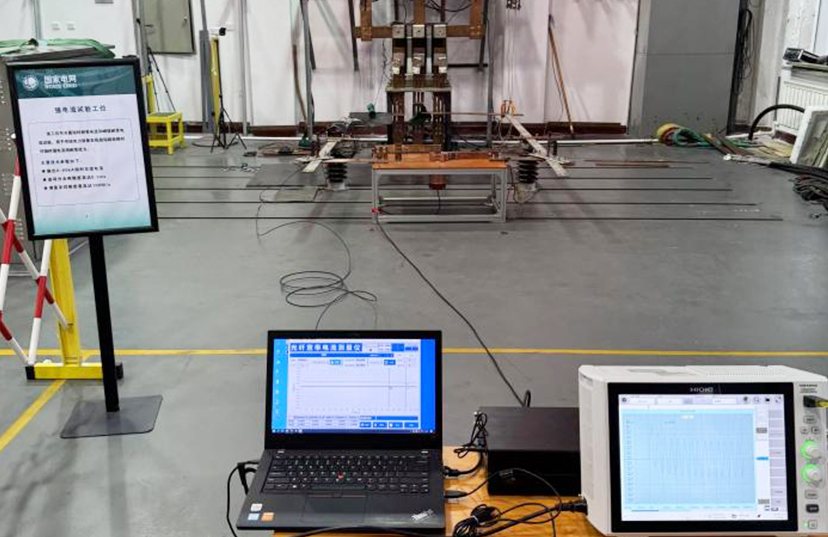

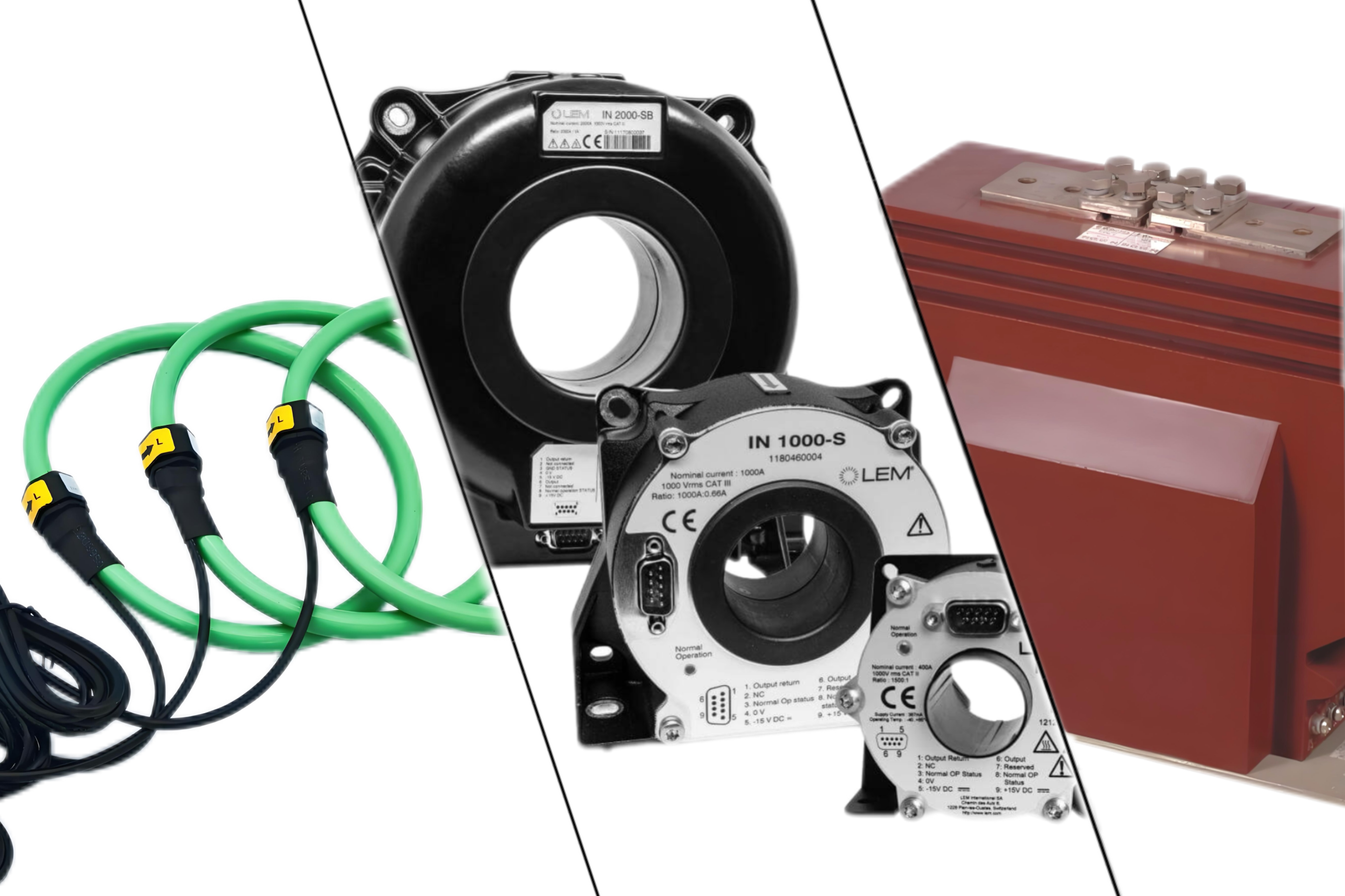

In the field of current sensors, optical fiber current sensors, due to their high precision, strong electromagnetic interference resistance, and excellent insulation performance, can meet the demands of various conventional and extreme environments, demonstrating exceptional adaptability to working conditions. They are widely used in scenarios including power supply current monitoring, electrical switch testing, and experimental centers at universities and research institutes. Additionally, thanks to their compact size and portability, optical fiber current sensors can replace traditional current transformers, simplify later calibration and calibration processes, and enable traceability with tracking reports.

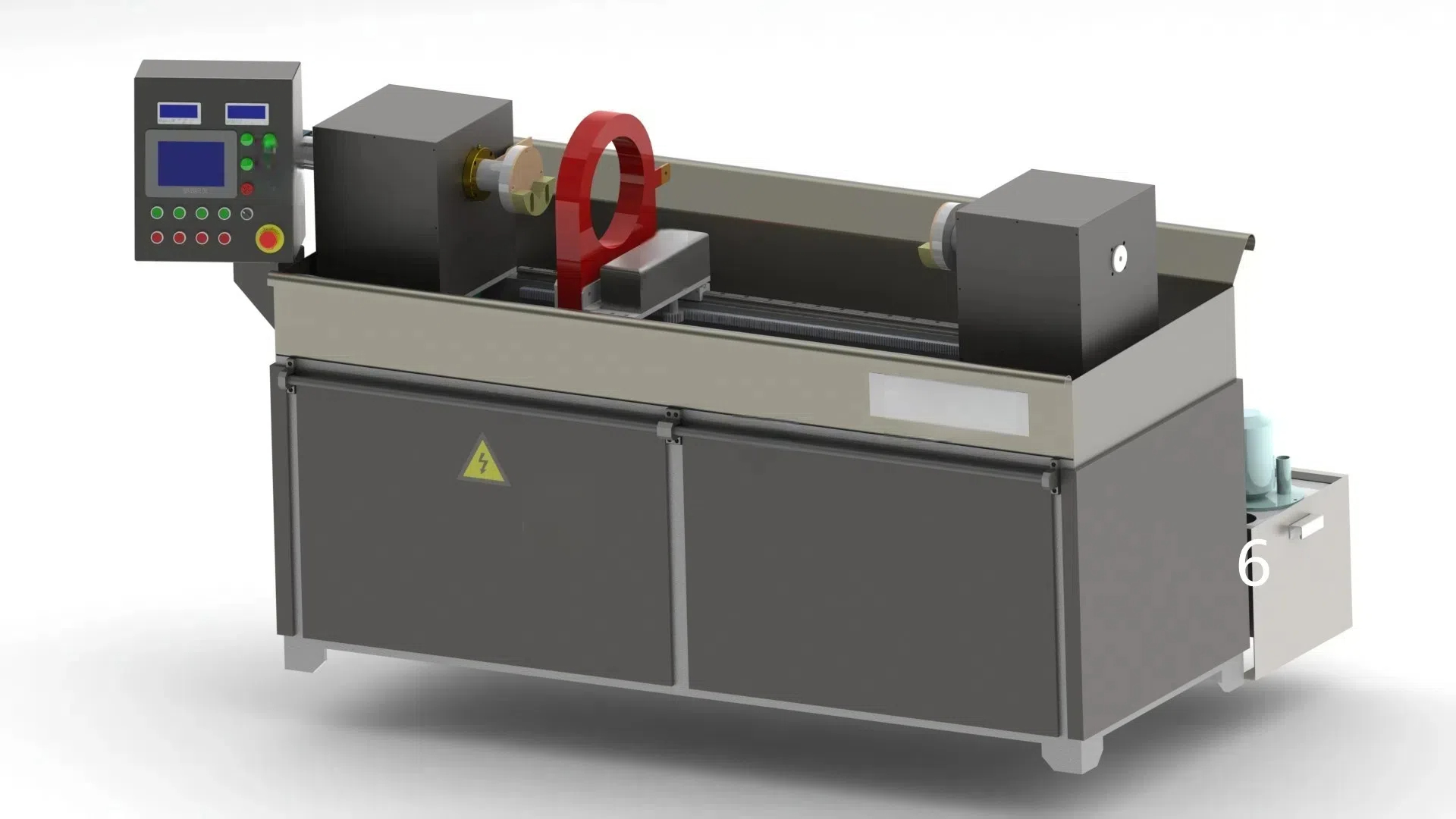

Current calibration of magnetic particle testing machines is essential for ensuring equipment safety, improving detection efficiency, and playing a key role in maintaining equipment performance. SIO Hand-held Fiber Optic Current Meter not only accurately captures current waveforms and reflects magnetization time for current calibration, but also, due to its compact size and portability, allows for on-the-go measurements. It is highly recognized by industry clients.

In the aluminum power plant, the high current output from the rectifier cabinet generates a strong magnetic field, which interferes with the normal work of the measuring equipment. Fiber optic current sensor is based on optical principle, which can effectively shield the surrounding strong electromagnetic field interference and ensure reliable data. Help enterprises to realize accurate current measurement and guide safe production.

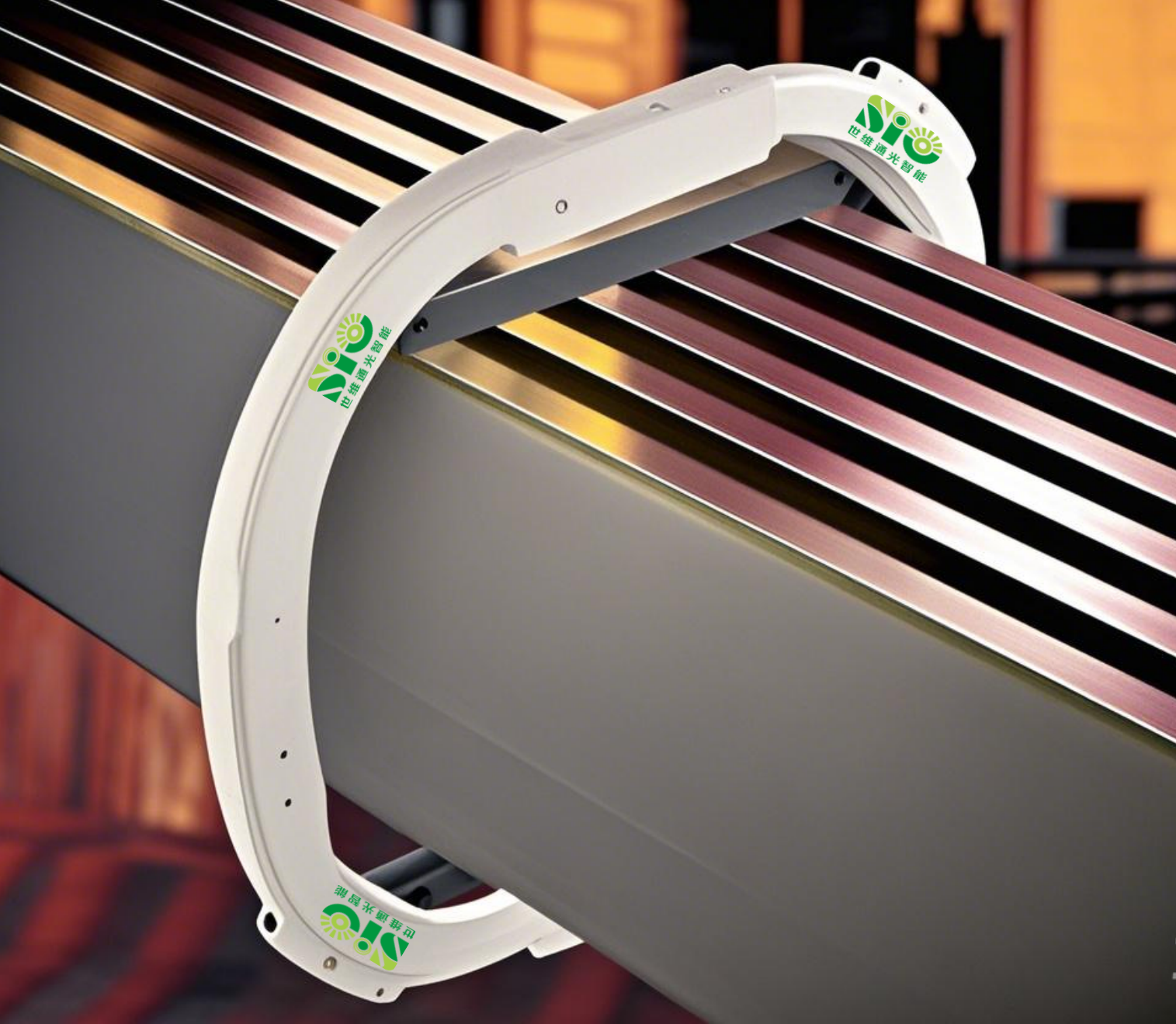

As a hub for power collection and distribution, the bus bar carries a huge amount of current, and its current stability is crucial to the entire smelting process. SIO Large DC Fiber Optic Current Sensors are more accurate, not subject to magnetic field interference, and can accurately measure the total series current of electrolysis tanks, which can provide accurate control signals for tank control machines and rectifier cabinets.

By analyzing the trend of cathode current distribution, early breakage of electrolysis cell can be detected and precise location can be realized. Compared with the traditional solution, it can greatly reduce the judgment time and avoid misjudgment.

By analyzing the anode current distribution of the electrolysis cell before and after the pole change, it can be used for lean control and timely discovery of low-voltage anode effect and anode long bag phenomenon.

In the process of aluminum electrolysis production, aluminum electrolysis cell as the core equipment, the stability of its current distribution is directly related to the production energy efficiency, tank life and product quality. However, traditional monitoring methods are limited by high temperature, strong magnetic field, and other complex working conditions, and there are problems such as low precision, difficult maintenance, and data lag. Our aluminum electrolysis cell online measurement system based on fiber-optic current sensor technology breaks through the problem of accurate measurement technology and field application of anode and cathode current distribution in electrolysis cell, subverts the current status quo of relying on the measurement of voltage drop and series current for production process control, provides accurate data support for electrolysis cell process improvement, intelligent control and health monitoring, and helps enterprises realize intelligent upgrading.

Traditional current sensors such as current transformers, Hall sensors, and Rogowski coils may experience drift errors and decreased accuracy during long-term daily use. Optical fiber current sensors, with their high precision and interference resistance, can replace standard sources for on-site calibration services. Currently, SIO has established partnerships with multiple calibration and testing organizations, and its products are widely used in the industry. Additionally, the on-site calibration services provided by our company can meet the on-site calibration needs across various industries.